Broach, Mill, Turn, Tap, Drill, Saw, Engrave etc. all in one setup!

Discover the game-changing benefits Gerard Machine offers, designed to optimize efficiency and cost-effectiveness for your operations.

- Streamlined Operations: Multiple operations that once required conventional CNC machines can now be seamlessly executed in a single setup, unlocking substantial cost savings.

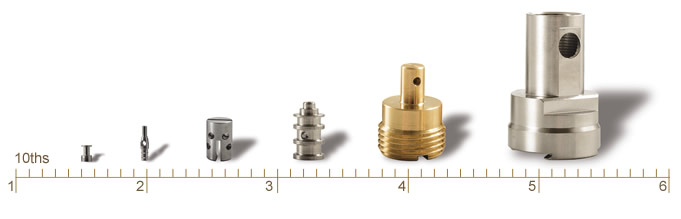

- Mastering Complexity: Complex parts requiring cross-drilling, tapping, broaching, milling, and more can now be flawlessly produced with one setup, ensuring faster turnaround times and reduced cycle times.

- Unparalleled Precision: With the ability to hold tolerances up to +/- .0001″, Gerard Machine guarantees impeccable accuracy, eliminating the need for additional grinding and ensuring superior surface finishes.

- Lights Out Machining: Our automatic bar feeders enable lights-out machining, maximizing productivity without compromising quality.

- Efficiency Redefined: Drawing from extensive manufacturing experience, we offer innovative part solutions that are both efficient and cost-effective, ensuring optimal results for your projects.

- Versatility in Materials: From aluminum, brass, copper, steel, stainless steel, titanium, to various types of plastics, Gerard Machine adapts to a wide range of materials, catering to your specific requirements.

- Swift Turnarounds: With faster part deliveries and a rapid quote turnaround, we prioritize your timelines, minimizing lead times and enhancing overall project efficiency.

- Comprehensive Inspection: Our full inspection reports, alongside the Mitutoyo optical comparator, guarantee meticulous scrutiny and precision in every component.

- Access to Outside Processes: Seamlessly incorporate outside processes such as heat treating, plating, anodizing, and more, all under Gerard Machine’s expert supervision.

- Technology-Driven Estimation: Leveraging CNC lathe cycle time estimating software, we optimize production schedules, ensuring maximum productivity and efficiency.

Experience the Gerard Machine difference, where precision, efficiency, and excellence converge, driving your company’s success to new heights.